Electric-heating Vacuum Emulsification Tank

We specialize in manufacturing food and medical equipment, and know you better! Widely used in food, beverage, pharmaceutical, daily chemical, petroleum and chemical industries

PRODUCT PARAMETERS

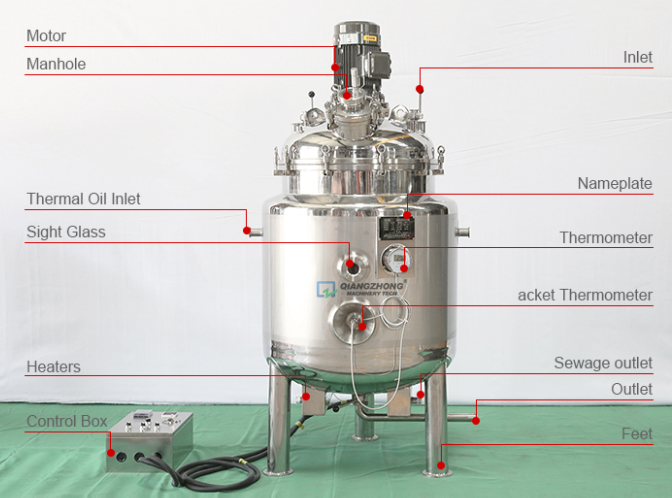

PRODUCT STRUCTURE

The emulsification tank is an advanced equipment which can mix, emulsily, homogenize, dissolve, crush materials of food, pharmaceuticals, chemicals and others. It can make one or more materials (water soluble solid phase, liquid phase, jelly, and etc.) dissolved in another liquid phase and make them into a relatively stable emulsion. When working, work head throws materials on center of rotor at high speed, materials passing through tooth space of stator, and finally achieve the purpose of emulsification by power of shear, collision and smash between rotor and stator. Its widely used for processing oil, powder, sugar and so on. Also it can emulsify and mix raw materials of some coatings, paint, and especially some difficult-soluble colloidal additives, such as CMC. xanthan gum.

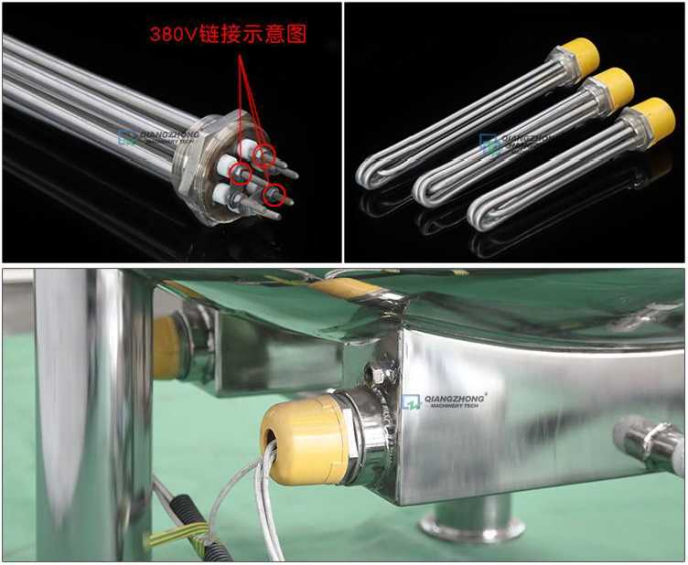

DISPLAY INTERNAL ELECTRIC HEATING

The advantages of the uniquely designed heaters connection:

1.Easy to install the heaters, no need special loading and unloading tools.

2.The heaters are completely filled into the tank body, ensuring a high heating efficiency.

3.Greatly reduce the cost of use and save energy.

WORKING PRINCIPLE

The centrifugal high-speed emulsifying work head can produce huge rotary suction force at work, rotate materials just above rotor to suck it down, and then throw it to stator at high speed. After high-speed shearing, collision and crushing between stator and rotor, materials collect and spray out from outlet. At the same time, swirling force of vortex baffle at the bottom of tank transforms into a up-and-down tumbling force, so that materials in the tank are mixed uniformly to prevent powder from agglomerating in liquid surface to achieve the purpose of hydration emulsification.

The centrifugal high-speed emulsifying work head can produce huge rotary suction force at work, rotate materials just above rotor to suck it down, and then throw it to stator at high speed. After high-speed shearing, collision and crushing between stator and rotor, materials collect and spray out from outlet. Pipeline high-shear emulsifier is equipped with 1-3 groups of dual occlusion multi-layer stators and rotors n the narrow cavity. Rotors rotate at high speed under driving of motor to generate strong axial suction, and materials are sucked into the cavity, recycling process materials. The materials are dispersed, sheared, emulsified in the shortest possible time, and finally we get fine and long-term stable products. High-speed emulsifier can efficiently, rapidly and evenly distributes one or more phases into another continuous phase, while in general the phases are incompatible. By high shear linear velocity generated by high-speed rotation of rotor and high kinetic energy brought by high-frequency mechanical effect, materials in the narrow gap of rotor and stator are forced by a strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tear and turbulence and other comprehensive effects. That makes incompatible solid phase, liquid phase and gas phase instantly homogenized, dispersed and emulsified under combined action of corresponding mature technology and proper amount of additives. Finally stable and high-quality products are available after repeated cycles of high-frequency.