Product Description

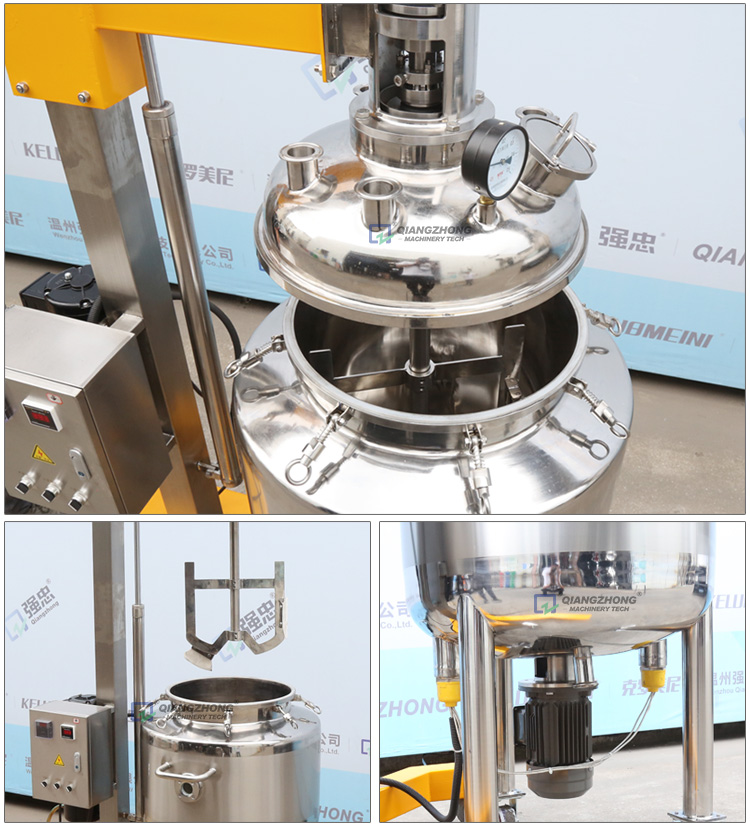

This tank is capable of distributing one or more phases to another continuous phase efficiently, quickly and uniformly, in which case the phases are mutually insoluble. Due to the high tangential speed and high-frequency mechanical effects generated by the high-speed rotation of the rotor, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction and impact in the narrow gap between the stator and the rotor. A combination of tearing and turbulence. Therefore, the incompatible solid phase, the liquid phase, and the gas phase are uniformly and finely dispersed and emulsified under the action of the corresponding mature process and an appropriate amount of additives, and the high-frequency cycle reciprocates to finally obtain a stable high-quality product.

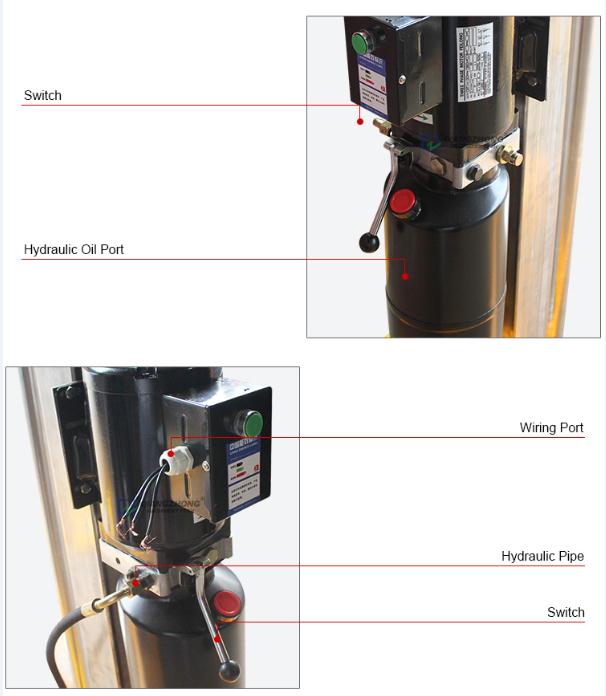

The mobile lifter can be divided into scissor mobile lifter, aluminum alloy mobile lifter.and folding-arm mobile lifter. The scissor mechanism of the scissor lifter ensure a higher stability when the lifter lifts, also it provides a large working platform and a high load carrying capacity, so that the operating range is larger, which makes it suitable for more people to operate the machine simultaneously. It makes operations more effcient and safer. Easy to replace,beautiful and generous. The use of pattern steel plate to load the weight of the equipment, instead of the old method of manual removal,it’s convenient, safe and durable. It is truly safe and efficient, saving time and effort

The mobile lifter mainly uses a hydraulic lifting frame and an electronic integrated controller,which can adjust the height in time and facilitate lifting.

For safety reasons,it is generally equipped with a non-slip plastic water wave engraving board, easyto replace, beautiful and generous.

lt is not as laborious as manual lifers, but truly safe and efficient, saving time and effort.

Precautions for Use and Maintenance

When the lifter is in use, the work surface should be kept horizontal.

When operating the machine at outdoors and in a poor environment, the user shoulduse a safety rope。 During ifting it is forbidden to climb the machine.

The fixed hydraulic ifter must not move after being ifted.No ifting operation is allowed when the four legs are not tightened

。it is forbidden to overload during use,and the contained items should be properly placed.

The hydraulic oil used should be kept clean and must not be mixed with water and other impurities. It is usually replaced every six months.

During maintenance or when there is a fault, the power supply should be cut off in time,and the lifter should be fixed firmly after ifting to perform other operations.