High Shear and Emulsification Magnetic Stirring Tank

Widely used in industries of brewery, dairy products, beverage, daily chemicals,bio-pharmaceuticals, etc. Mix, disperse, emulsify, homogenize, transport, batch

国I PRODUCT PARAMETERS

bio-pharmaceuticals, etc. Mix, disperse, emulsify, homogenize, transport, batch

国I PRODUCT PARAMETERS

|

Volume (L) |

Diameter (mm) |

Stirring Speed (r/min) |

Tank Pressure (MPa) |

Pressure (Mpa) |

|

100 |

550 |

24-120 RPM (optional) |

Atmospheric/ Pressurized |

0.25 |

|

200 |

600 |

|||

|

500 |

800 |

|||

|

1000 |

1000 |

|||

|

1500 |

1200 |

|||

|

2000 |

1200 |

|||

|

2500 |

1400 |

|||

|

3000 |

1400 |

|||

|

4000 |

1500 |

|||

|

5000 |

1500 |

The data is measured by water as a liquid medium and white sugar as a solid phase medium. Liquid phase viscosity, solid phase density and water content have a great influence on the yield.

The equipment can be customized according to the customer’s materials to meet the needs of the process, such as meeting the requirements of high viscosity, homogenization function enhancement, heat sensitive materials, etc.

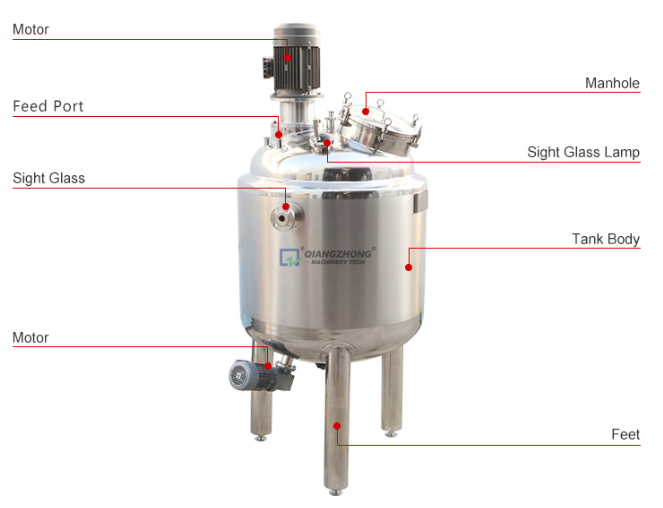

PRODUCT STRUCTURE

Magnetic Stirrer Parameters

|

Model No. |

Motor Power (kw) |

Speed (RPM) |

Stirring Capacity (L) |

|

QLK-50L |

0一25 |

450 |

10-50L |

|

QLK-100L |

0.25 |

450 |

50-100L |

|

QLK-500L |

0.55 |

450 |

100-500L |

|

QLK-1000L |

0.55 |

450 |

500-1000L |

|

QLK-2000L |

1.1 |

450 |

1000-2000L |

|

QLK-5000L |

2.2 |

450 |

2000-5000L |

|

QLK-10000L |

3 |

355 |

5000-10000L |

|

QLK-20000L |

4 |

355 |

10000-20000L |

High Shear Emulsifier Type Parameters

|

Model No. |

Motor Power (kw) |

Motor Speed (r/min) |

Capacity (L) |

D |

D1 |

P |

L |

M I |

|

|

WRL-90 |

1.5 |

2900 |

10-50 |

80 |

140 |

200 |

355 |

165 |

|

|

WRL-100 |

2,2 |

2900 |

50-100 |

88 |

145 |

200 |

650 |

165 |

|

|

WRL-120 |

4 |

2900 |

100〜300 |

120 |

180 |

250 |

750 |

215 |

|

|

WRL-140 |

7.5 |

2900 |

300-800 |

140 |

210 |

300 |

900 |

265 |

|

|

WRL-160 |

11 |

2900 |

500-1500 |

160 |

230 |

350 |

1050 |

300 |

|

|

WRL-180 |

18.5 |

2900 |

600-2000 |

180 |

260 |

350 |

1200 |

300 |

|

|

WRL-200 |

22 |

1450-1500 |

800-2500 |

200 |

270 |

350 |

1200 |

300 |

|

|

WRL-220 |

30 |

1450-1500 |

1000-3500 |

240 |

320 |

400 |

1355 |

350 |

|

|

WRL-240 |

37 |

1450-1500 |

1500〜5000 |

260 |

340 |

400 |

1395 |

350 |

Magnetic mixing tank has characteristics of no leakage, fully sealed, corrosion resistance and energy saving. Because of its non-contact transmission torque, taking static seal to replace dynamic seal, it solves the leakage problem that other shaft seals cannot overcome. Since all materials and the mixing components operate in a sterile and sanitary state, the magnetic mixing tank is an ideal replacement for processing machines in the industries of pharmaceutical, fine chemicals, cosmetics and bioengineering. It is a sterile liquid mixing tank with mixing device installed at the bottom or sideways if necessary, enabling CIP and SIP. There can be different seal heads, jackets or single wall, from which customers can choose for different combinations according to requirements.

PRODUCT STRUCTURE

Optional Configuration for Tank Body

Aseptic air filter, thermometer (digital or dial type), pH meter, steam sterilization port, spotlight sight glass, sanitary manhole, liquid inlet and outlet, CIP swivel cleaning ball, pressure gauge, sterile sampling valve (at the tank bottom), liquid level gauge, automatic liquid level control system (load-bearing module, non-contact ultrasonic, static pressure transmitter), and etc., Other accessories could be equipped according to customer’s requirements

Typical Application

It can be used as liquid storage tank, mixing tank, temporary storage tank, water storage tank, and etc. It is suitable for aseptic mixing and storage of liquid materials in the fields of food, dairy products, juice drinks, pharmaceutical chemicals, biological engineering and etc.

Product Features

- Welded isolation sleeve static dead seal replaces dynamic mechanical seal, that completely solves the leakage problem of dynamic mechanical seal, ensuring no leakage, no external pollution, strong safety and it’s simple structure, easy to disassemble and clean, no dead corner.

- A mixer at the bottom even can mix very few materials with unique designed mixing blade, mixing speed ranging from 20r/min to 400r/min, which can mix and blend various materials. Since the mixer is installed at an angle of 10°at the tank bottom, the materials are twisted within the tank at an angle of 10°during agitation, not rotating in the circumferential direction, bringing about turbulent flow.

- The mixing speed is regulated steplessly by the inverter, and the optimal mixing speed can be adjusted below the maximum speed to meet the requirements of various processes on the mixing speed.

- Tank capacities available range from 50L to 20.000L, which could be designed and manufactured according to actual needs of customers.