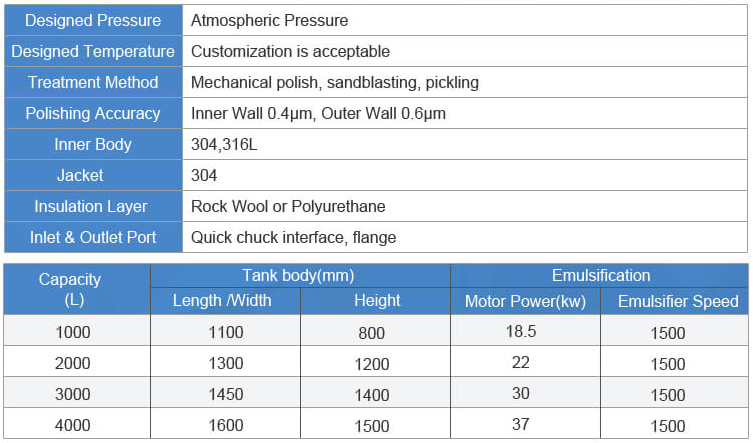

Product Parameters

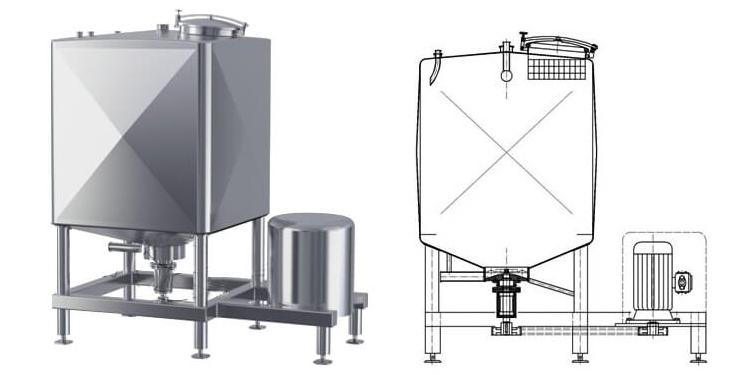

Product Structure

It adopts high-speed impeller as the stirring device at the bottom, which has good dissolution and emulsification effect on sugar, milk powder, and glue additives in production. It is currently the most productive equipment in emulsified tank products.

It is with a rectangular single-layer tank body, and the internal wall of the tank transition section is arc transition, no health corner, easy to clean. The tank body and lower head can be provided with insulation layers according to customer requirements.

Optional Configuration

Sterile air filter, thermometer (digital or dial type), sight glass, sanitary hole, inlet and outlet holes, CIP swivel cleaning ball, sterile sampling valve (stainless steel tank Bottom), liquid level gauge and liquid level automatic control system (load-bearing module, non-contact ultrasonic, static pressure transducer), etc. It can also be configured according to customer requirements.

Typical Application

Applicable to food, dairy, beverage, biological engineering, pharmaceuticals, fine chemicals, pigments and other industries, making emulsions and mixtures inside the tank fully and quickly mixed, dispersed, emulsified and homogenized.

Product Features

● Tank capacity could be 600L ~ 5,000L, which can be designed and manufactured according to needs of customers.

● Quick chuck interface and tank body is made of 304 or 316L stainless steel. The inner surface is mirror-polished Ra≤0.28μm~0.6μm and the outer surface can be polished, brushed, sandblasted or other treatment according to customer requirements.

● It adopts mechanical emulsification at the bottom, with claw-type bite and two-way sucking structure to avoid dead angle and vortex phenomenon caused by difficult suction of upper materials. High-speed stirring and emulsification can be used to mix, disperse, emulsify, and homogenize different emulsions and mixtures.

● The emulsifying shaft is sealed with sanitary mechanical seal. The emulsified motor can be a cycloid reducer, a stepless speed reducer, or customized according to customer requirements.