Video

Suitable for mixing milk powder, whey powder, calcium milk and other fluids.

The main function is to use a high-speed rotating impeller to fully stir powdery materials and liquids, deliver the mixture, and also used for producing fruit juices and other beverages.

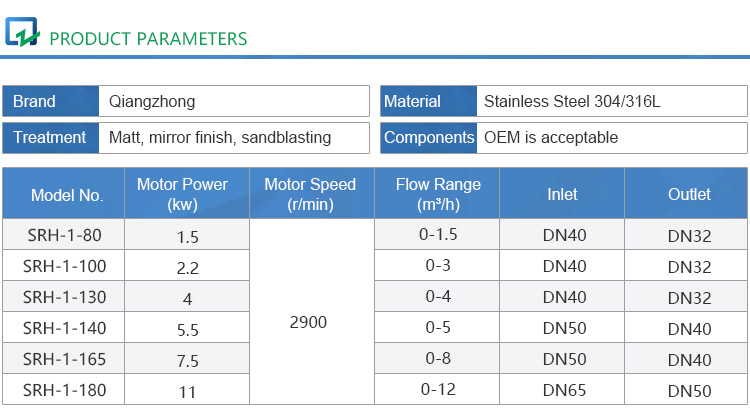

Product Parameter

| Brand:

Surface Treatment: Components: Product Name: Materials: Application: |

Qiangzhong

Matte, Mirror, Sandblasting Customization is acceptable Cam Rotor Pump ZB3A Series 304/316 Stainless Steel Pharmaceuticals, brewery, food, chemicals, etc. |

Product Advantages

High-quality Stainless Steel Material

The pump is made of 304/316L stainless steel, bear high temperature up to 800 degrees, widely used in industries of food, medicals, etc.

The butterfly valve can be rotated 90 degrees quickly, with good fluid control characteristics and close sealing performance.

Excellent Motor Unit

The motor has many advantages such as high power, large torque, low temperature rise, low vibration, etc. The three-phase motor directly drives the grinding head to rotate, saving grinding time.

Connection Method

There are three types of connection. The first type is the most commonly used clamp connection, also called quick connection. The second type is a screw connection. The third type is a flange connection. The default connection method is a quick connection.

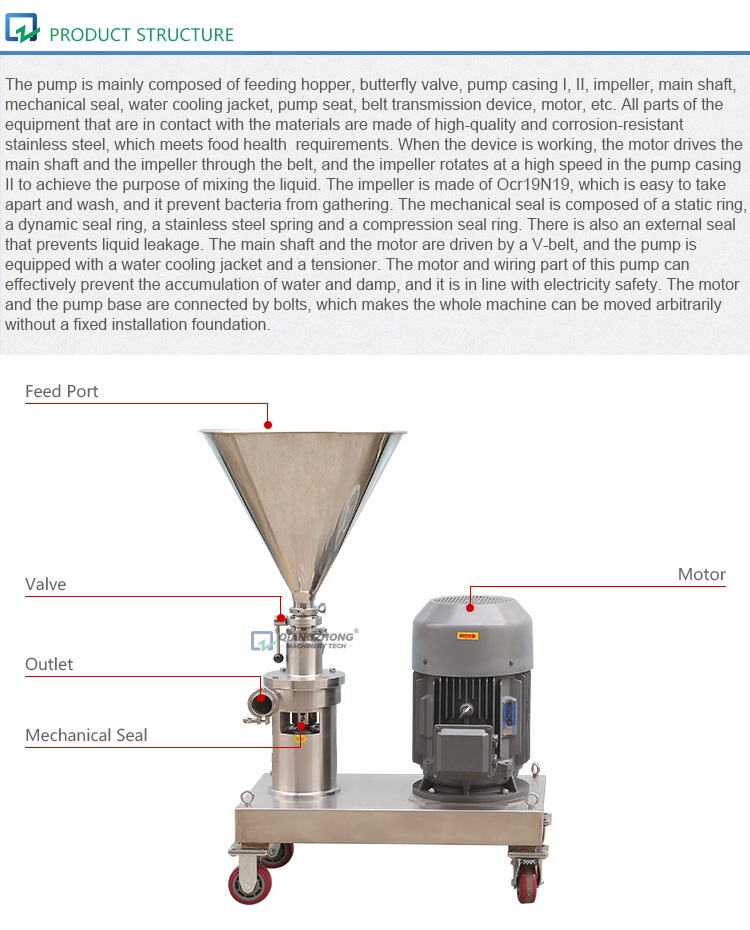

Product Structure

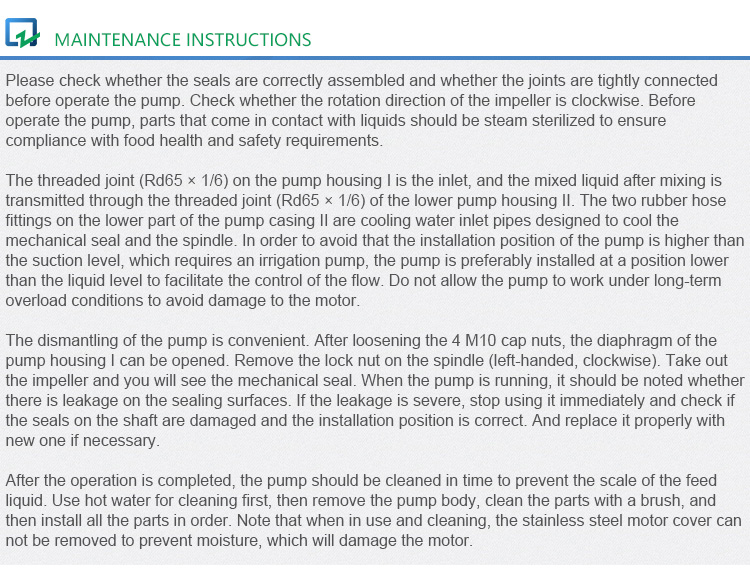

The pump is mainly composed of feeding hopper, butterfly valve, pump casing I, II, impeller, main shaft, mechanical seal, water cooling jacket, pump seat, belt transmission device, motor, etc. All parts of the equipment that are in contact with the materials are made of high-quality and corrosion-resistant stainless steel, which meets food health requirements. When the device is working, the motor drives the main shaft and the impeller through the belt, and the impeller rotates at a high speed in the pump casing II to achieve the purpose of mixing the liquid. The impeller is made of Ocr19N19, which is easy to take apart and wash, and it prevent bacteria from gathering. The mechanical seal is composed of a static ring, a dynamic seal ring, a stainless steel spring and a compression seal ring. There is also an external seal that prevents liquid leakage. The main shaft and the motor are driven by a V-belt, and the pump is equipped with a water cooling jacket and a tensioner. The motor and wiring part of this pump can effectively prevent the accumulation of water and damp, and it is in line with electricity safety. The motor and the pump base are connected by bolts, which makes the whole machine can be moved arbitrarily without a fixed installation foundation.

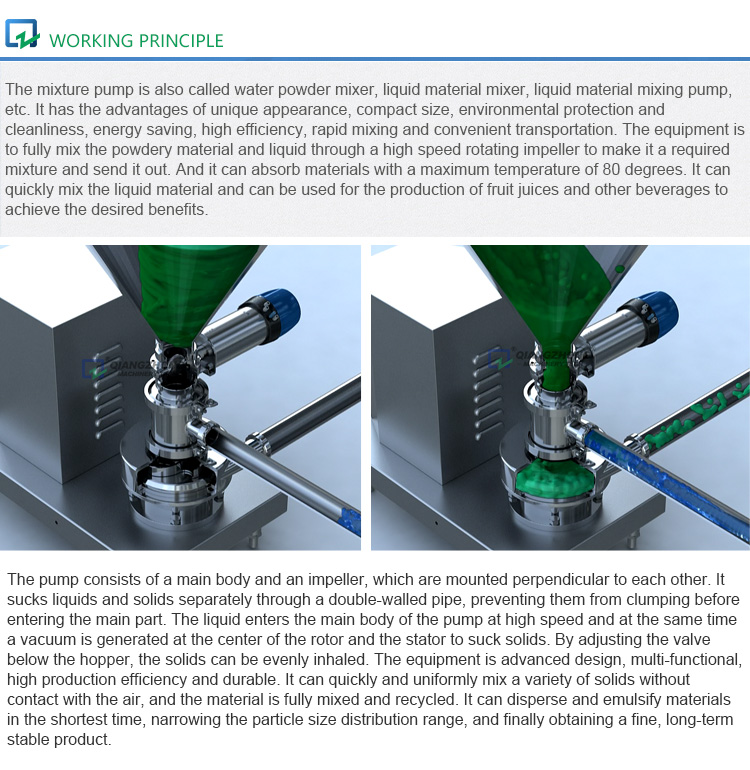

Working Principle

The mixture pump is also called water powder mixer, liquid material mixer, liquid material mixing pump, etc. It has the advantages of unique appearance, compact size, environmental protection and cleanliness, energy saving, high efficiency, rapid mixing and convenient transportation. The equipment is to fully mix the powdery material and liquid through a high speed rotating impeller to make it a required mixture and send it out. And it can absorb materials with a maximum temperature of 80 degrees. It can quickly mix the liquid material and can be used for the production of fruit juices and other beverages to achieve the desired benefits.

The pump consists of a main body and an impeller, which are mounted perpendicular to each other. It sucks liquids and solids separately through a double-walled pipe, preventing them from clumping before entering the main part. The liquid enters the main body of the pump at high speed and at the same time a vacuum is generated at the center of the rotor and the stator to suck solids. By adjusting the valve below the hopper, the solids can be evenly inhaled. The equipment is advanced design, multi-functional, high production efficiency and durable. It can quickly and uniformly mix a variety of solids without contact with the air, and the material is fully mixed and recycled. It can disperse and emulsify materials in the shortest time, narrowing the particle size distribution range, and finally obtaining a fine, long-term stable product.

Following control components are optional

☉Pneumatic valve

☉ high-low level sensor

☉ Pneumatic or electric vibrators

The pump can be equipped with an exchange station for operating and protecting the machine.

The standard exchange station has the following basic functions:

Stop/start

emergency stop

Motor protection

Vibrator type

☉ Pneumatic Vibrator: This vibrator is made by rolling a roller on a steel tank. Its frequency can be changed by adjusting the air which enters the vibrator.

☉ Electric vibrators: The motor is centrally located on each side of the axis of rotation to provide the necessary vibration. The rotating shaft generates a centrifugal force that can be changed by changing the mass.

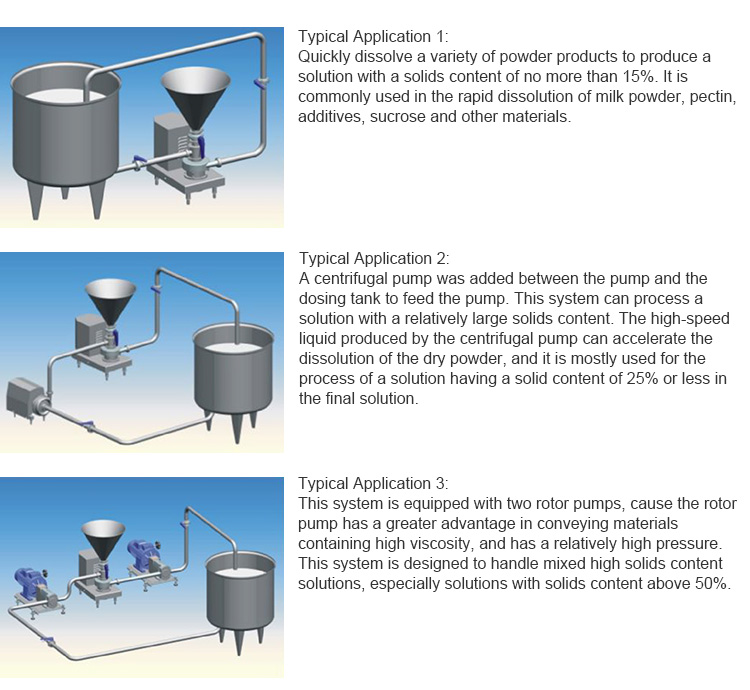

Typical Application 1:

Quickly dissolve a variety of powder products to produce a solution with a solids content of no more than 15%. It is commonly used in the rapid dissolution of milk powder, pectin, additives, sucrose and other materials.

Typical Application 2:

A centrifugal pump was added between the pump and the dosing tank to feed the pump. This system can process a solution with a relatively large solids content. The high-speed liquid produced by the centrifugal pump can accelerate the dissolution of the dry powder, and it is mostly used for the process of a solution having a solid content of 25% or less in the final solution.

Typical Application 3:

This system is equipped with two rotor pumps, cause the rotor pump has a greater advantage in conveying materials containing high viscosity, and has a relatively high pressure. This system is designed to handle mixed high solids content solutions, especially solutions with solids content above 50%.

Maintenance Instructions

Please check whether the seals are correctly assembled and whether the joints are tightly connected before operate the pump. Check whether the rotation direction of the impeller is clockwise. Before operate the pump, parts that come in contact with liquids should be steam sterilized to ensure compliance with food health and safety requirements.

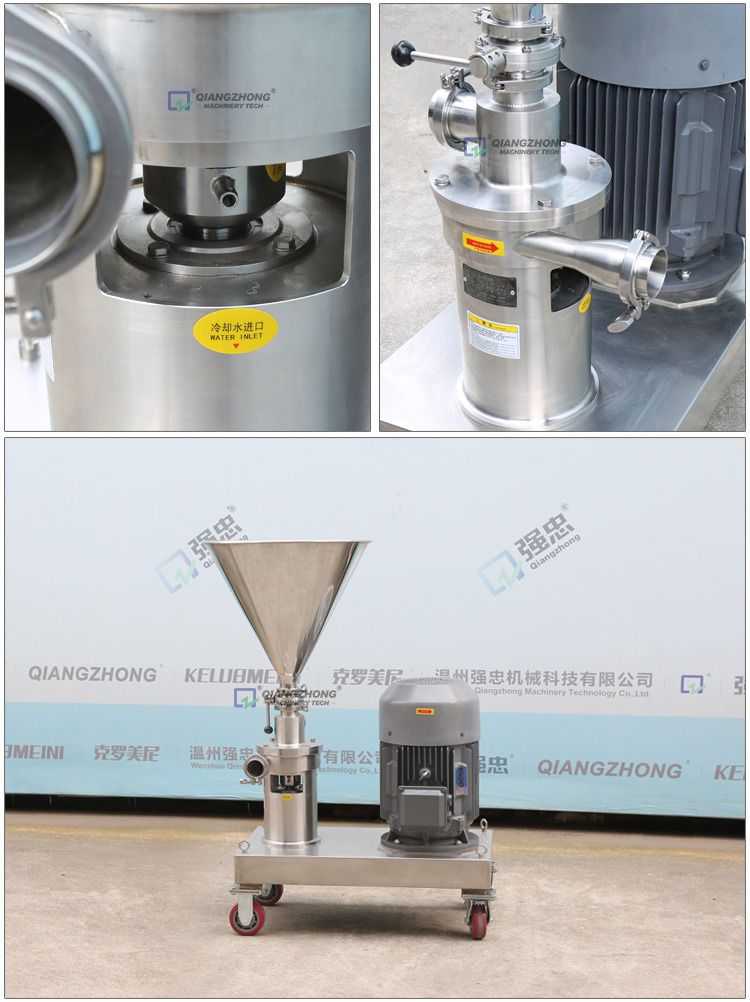

The threaded joint (Rd65 × 1/6) on the pump housing I is the inlet, and the mixed liquid after mixing is transmitted through the threaded joint (Rd65 × 1/6) of the lower pump housing II. The two rubber hose fittings on the lower part of the pump casing II are cooling water inlet pipes designed to cool the mechanical seal and the spindle. In order to avoid that the installation position of the pump is higher than the suction level, which requires an irrigation pump, the pump is preferably installed at a position lower than the liquid level to facilitate the control of the flow. Do not allow the pump to work under long-term overload conditions to avoid damage to the motor.

The dismantling of the pump is convenient. After loosening the 4 M10 cap nuts, the diaphragm of the pump housing I can be opened. Remove the lock nut on the spindle (left-handed, clockwise). Take out the impeller and you will see the mechanical seal. When the pump is running, it should be noted whether there is leakage on the sealing surfaces. If the leakage is severe, stop using it immediately and check if the seals on the shaft are damaged and the installation position is correct. And replace it properly with new one if necessary.

After the operation is completed, the pump should be cleaned in time to prevent the scale of the feed liquid. Use hot water for cleaning first, then remove the pump body, clean the parts with a brush, and then install all the parts in order. Note that when in use and cleaning, the stainless steel motor cover can not be removed to prevent moisture, which will damage the motor.