The surface finish of high-purity stainless steel piping systems plays a very important role in the safe production of food and medicine. Good surface finish is washable, reduces microbial growth, corrosion resistance, and removes metal impurities. In order to improve the surface quality of the stainless steel pipe system, that is, to improve the surface morphology and morphological structure, and to reduce the number of layers, the common surface treatment methods are as follows:

1. Mechanical grinding and polishing (Mechanically Polished) called MP

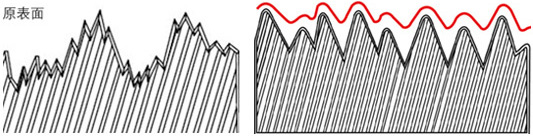

Fine surface grinding to improve surface roughness can improve surface texture without improving morphological structure, energy levels, and number of layers.

2. Buffed Polished (Buffed Polished) referred to as BP

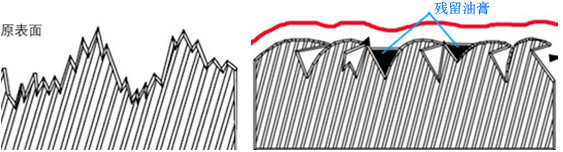

The way commonly used in the stainless steel industry to increase the brightness of the surface, although the Ra value may be very good, many cracks can be observed under the electron microscope, the actual surface area is enlarged, and the separated ferrite and martensite structure are locally. The surface is contaminated with many impurities as well as abrasive particles.

Due to the use of polishing paste, many unclean residues are stored in the depressions and gradually released into the fluid, contaminating the food.

3. Pickled or passivated (Pickled & Passivated / Chemically Polished) referred to as AP and CP

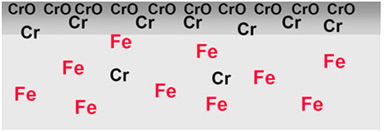

The pipe is pickled or passivated without increasing the surface roughness, but it removes residual particles on the surface and reduces energy levels without reducing the number of layers. A passivation protective layer of chromium oxide is formed on the surface of the stainless steel to protect the stainless steel from corrosion oxidation.

4. Electro Polishing (Electro Polished) referred to as EP

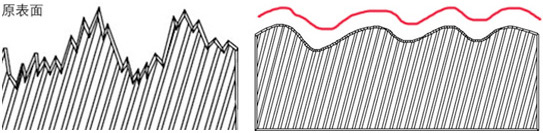

By electrochemical polishing, the surface morphology and structure can be greatly improved, and the actual surface area can be minimized. The surface is a closed, thick chrome oxide film with energy close to the normal level of the alloy and the amount of media is minimized.

In order to achieve a perfect electropolishing result, mechanical polishing must be abrasive polishing.

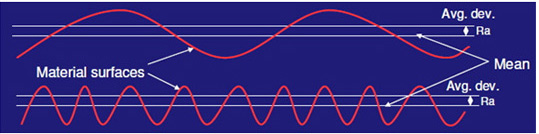

It should be noted that the same Ra value does not represent the same surface treatment.