PriceList for Groundnut Oil Production Machine - Single-bag Filter – Qiangzhong Detail:

Bag filters are mainly used to filter impurities in water, beverages, and chemical liquids. The filter bags are available in #1, #2, #3, #4, etc., and a stainless steel filter basket is required as a support. The filter has a large filtering area, high filtration efficiency, convenient operation and low maintenance cost. The height of the filter is adjustable for different applications.

Typical Application

•Food, beverage, and alcohol factories, meeting the sanitary requirement

•Filtration of petrochemical and chemical products

•Filtration of liquids in printing, furniture, etc.

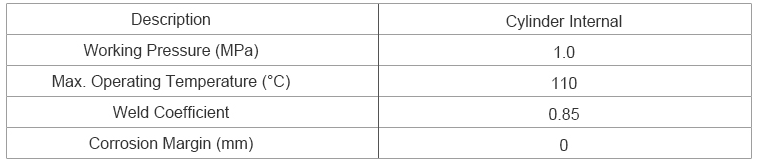

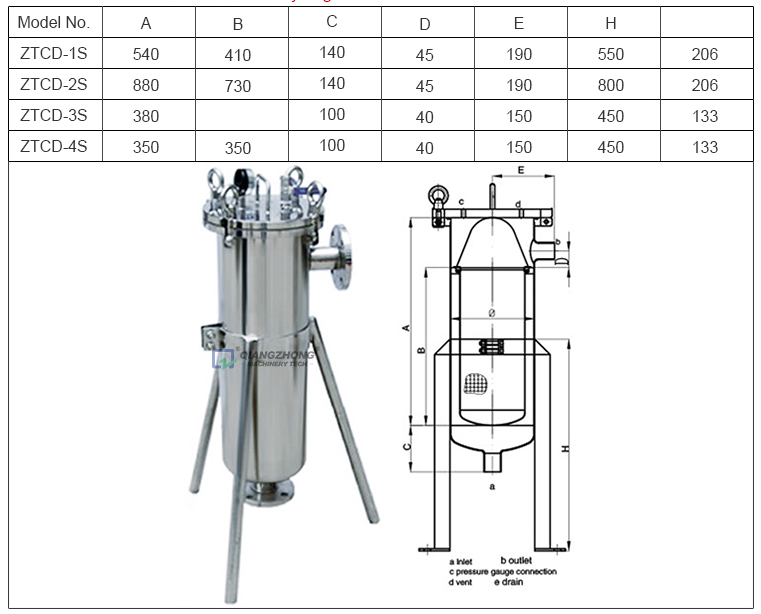

Technical Apecofocation

Main Technical Parameters of Side-entry Bag Filter

Main Technical Parameters of Top-entry Bag Filter

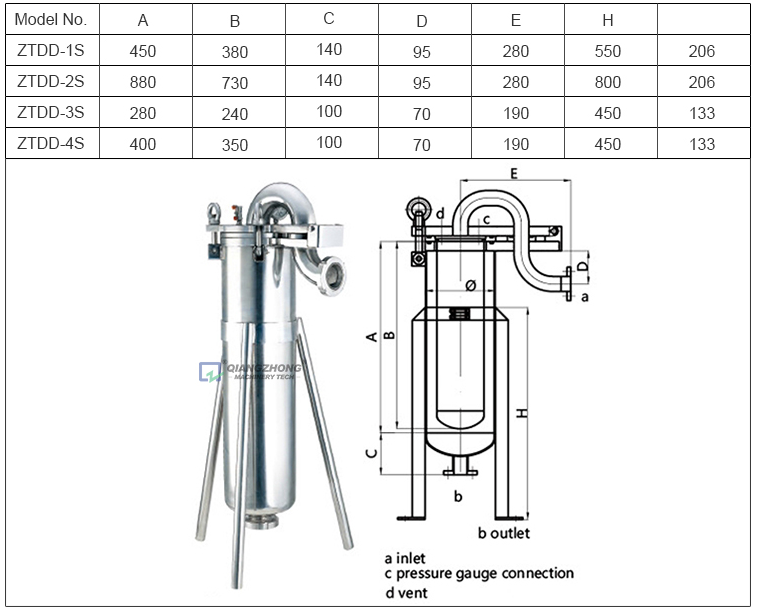

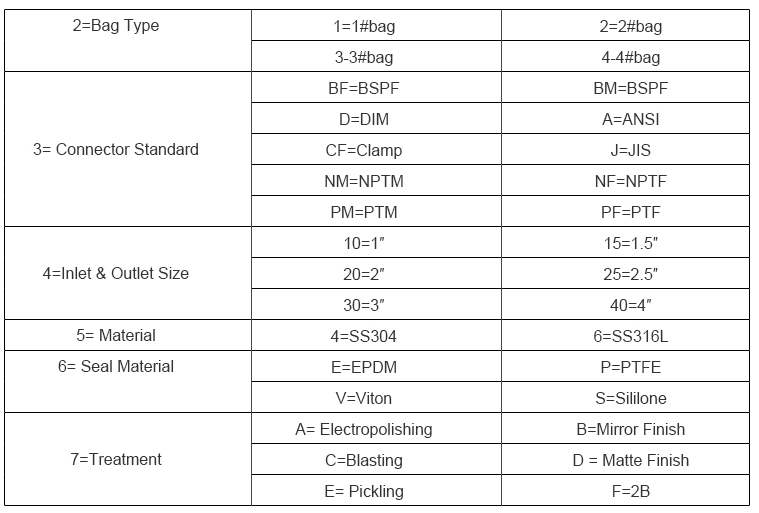

Seleciton Guide

Pleated Filter Cartridge

Liquid Filter Bag Type: bag filter Application: liquid filtration Bag Material: PE / PP / other Accuracy: 1-200UM

The ordinary liquid filter bag is made of PE (polyester) fiber, PP (polypropylene) fiber cloth, or MO (monofilament) mesh. PE and PP are deep three-dimensional filter materials. 100% pure fiber is processed by needle punching to form a three-dimensional, high-floating and tortuous filter layer. The 100% pure fiber is needle-punched into a three-dimensional, highly fluffy and tortuous filter layer. It is characterized by loose fibrous structure, which can increase the capacity of impurities. This filter is a double-cut mode that effectively removes solid and soft particles, allowing larger particles to be trapped on the fiber surface while fine particles are trapped in the depth of the filter. It ensures that it will not break due to increased pressure during use and has high filtration efficiency. In addition, the outer surface of the machine is high-temperature heat treatment, that is, instant sintering technology (calendering treatment), which can effectively prevent the fibers from being lost by high-speed impact of liquid during filtration. Thereby, both the contamination of the filtrate due to fiber detachment and the clogging of the filter pore caused by the conventional rolling treatment could be avoided, and the life of the filter bag is increased. In addition, this pressure difference is small, that does not affect the flow rate, and its accuracy is 1-200microns

MO is made of non-deformable nylon spinning, woven into a net according to the specified specifications, and becomes a single wire after heat setting. It is characterized by high strength and does not deform due to changes in pressure. The monofilament woven surface is smooth, easy to clean, and can be used repeatedly. It is also suitable for filtering some liquids with high impurity content, which can reduce the filtration cost, and its precision is 20 〜 550 mesh(25~840μm).

Filter bag fixing ring material: stainless steel ring, galvanized steel ring, polyester / polypropylene plastic ring

Material: Polyester (PE), Polypropylene (PP).

L = five-line seam – ring material (common galvanized steel, stainless steel)

A= bag 1, B= bag 2, C=bag 3, D= bag 3

Filtration area: bag 1 = 0.25, bag 2 = 0.5, bag 3 = 0.8, bag 3 = 0.15

Dimensional tolerance mm: >0.3-0.8 >0.3-0.8 >0.3-0.8 >0.3-0.8

Filtration fineness (pm): 1, 3, 5,10,15,20,25, 50,75,100,150,200

Maximum Operating Pressure Difference (MPa): 0.4, 0.3, 0.2

Maximum Operating Temperature (°C): Polyester (PE): 130 (instantaneous 180); Polypropylene (PO):

90 (instantaneous 110)

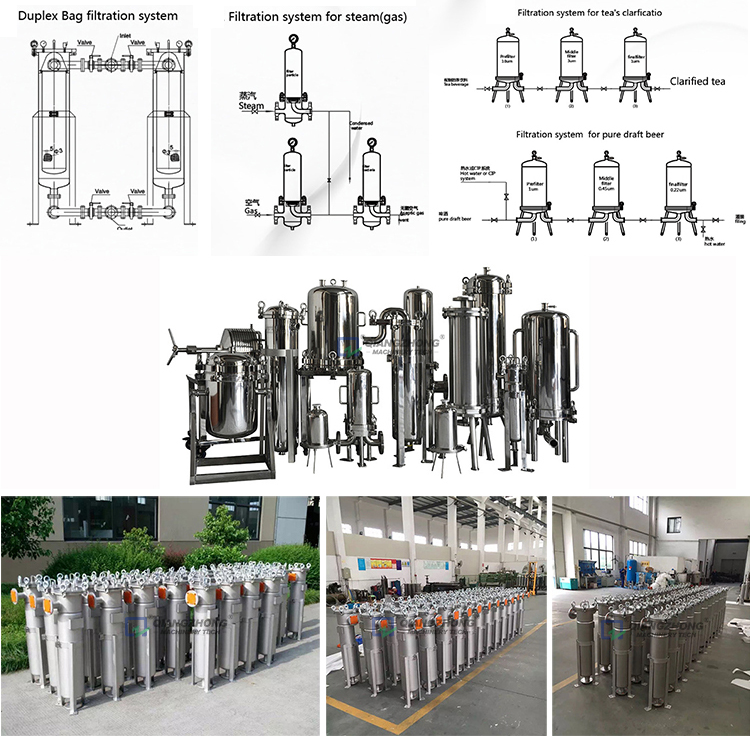

Filter System Application

Product Showcase

Product detail pictures:

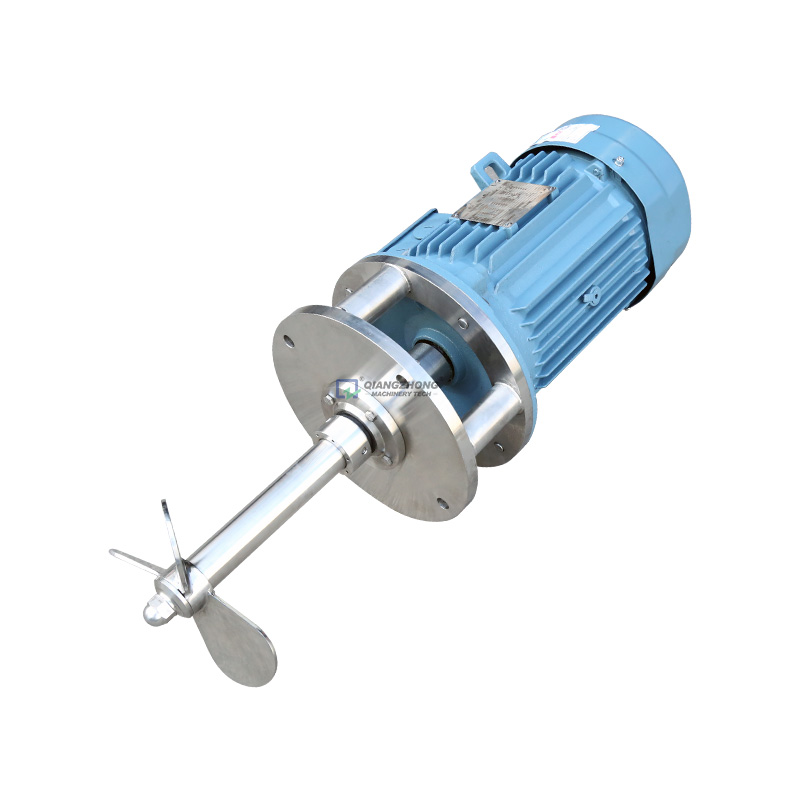

Related Product Guide:

Cooperation

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for PriceList for Groundnut Oil Production Machine - Single-bag Filter – Qiangzhong, The product will supply to all over the world, such as: European, Greenland, Madrid, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.