Video

Specialized in manufacturing food and medical equipment, we know you better.

Widely used in food, beverage, pharmaceutical, daily chemical, petroleum, etc. industries.

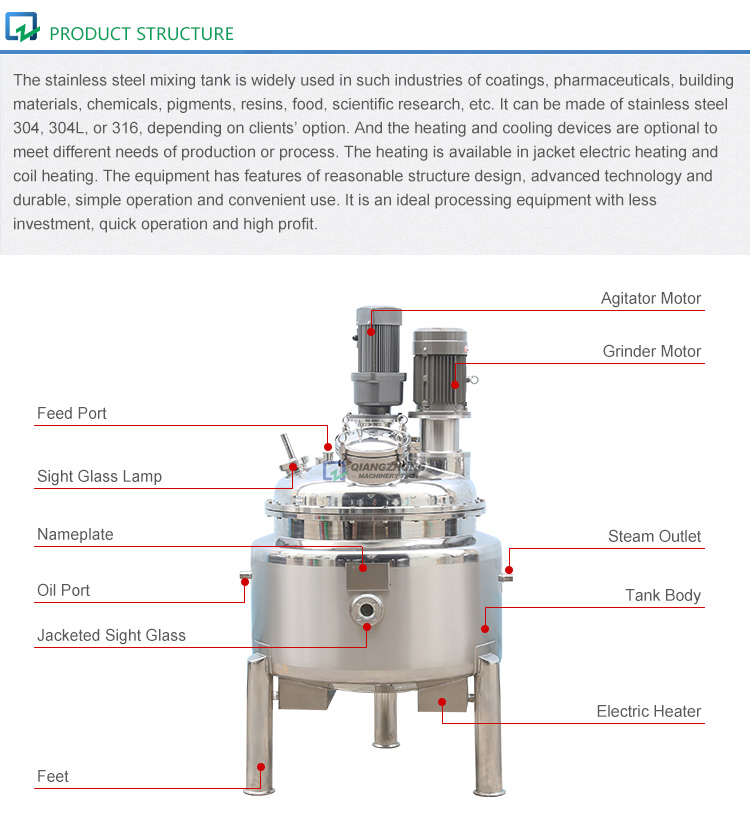

The hydraulic lifting basket grinder integrates dispersion and grinding, and is suitable for wet grinding of medium and low viscosity fluids. It is a batch industrial production equipment with reasonable design of the grinding basket structure, and the equipment is easy to clean, and also easy to change color and materials. The lifting structure adopts hydraulic oil cylinder, which is stable in lifting. And the integrated oil tank is environmentally friendly and has no leakage. This machine is an ideal grinding equipment for multi-variety and multi-color products.

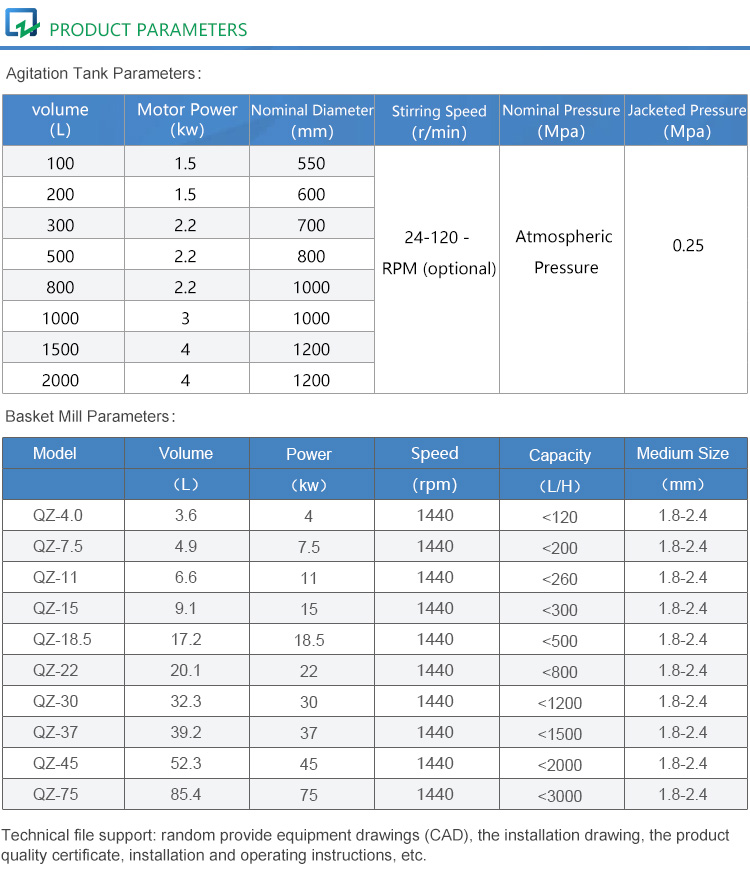

Configuration Parameter

Motor origin: Shanghai

The jacket cylinder is made of stainless steel SS304. The jacket pressure resistance is 2kgf/㎡.

The chilled water pressure is 2kgf/㎡of tap water.

Flow rate: 10L/min.

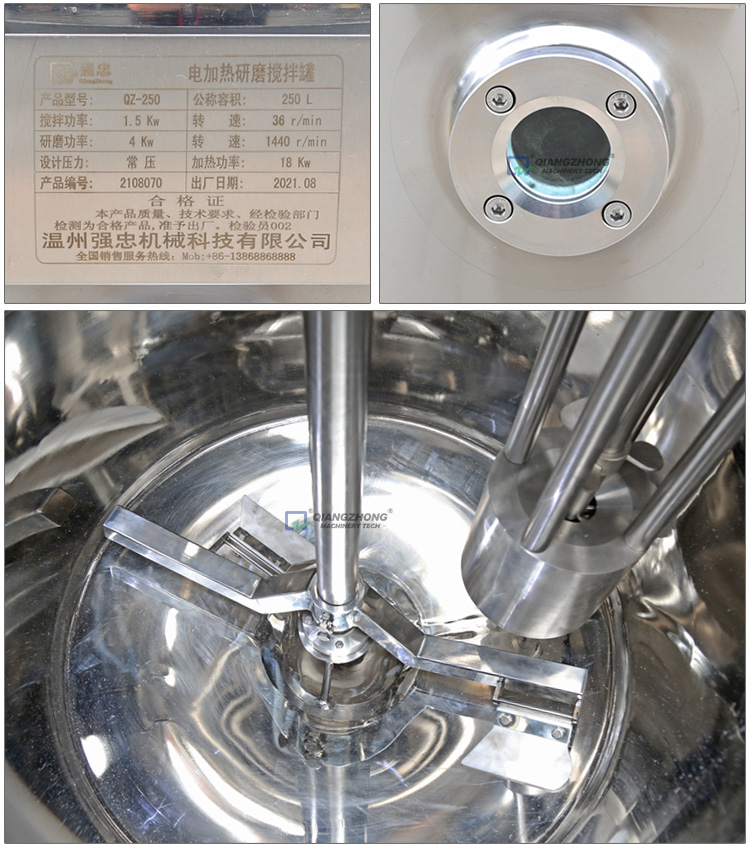

The transmission shaft is made of stainless steel SS304 with thermal refining treatment, the surface is plated with hard chrome, and the plating layer is above 0.15-0.2mm.

Impeller material: stainless steel SUS304, the grinding basket rod adopts zirconia material structure.

Screen material: stainless steel SUS304, surface with wear-resistant treatment (nitriding heat treatment), the hardness is about HRV1000.

Dispersion disc material: stainless steel SUS304, wear-resistant treatment.

Zirconia beads:

Origin: Germany Nanor, with 95% zirconium content.

True specific gravity: 6.0g/cm³

Bulk weight: 3.6g/cm³

Applicable materials: fluid slurry

Fineness: 5-20um

Grinding Media: pure Zirconia beads with zirconium content ≥95%, the diameter of the grinding media used is 1.6mm-2.4mm

Electric control system: with on-site operation panel (touch screen / frequency conversion stepless speed regulation is optional)

1. Used for the dispersion and grinding of small batch products (50-2000 liters);

2. Integrating dispersing and grinding, no need to equip dispersing machine;

3. With 3-phase power supply, strong power

4. The part in contact with the material is made of high-quality 304 stainless steel,

mirror-polished, and the material is not easy to remain, and it is easy to clean;

5. The grinding container adopts a double wall structure for cooling, which is convenient for discharging the heat generated during the grinding process

6. The grinding cylinder is airtight during the grinding process, but the material can be inspected and evaluated through the sampling port at any time;

7. The standard configuration is a grinding cylinder with a jacket. In addition, various sizes of stainless steel double-wall grinding containers can be customized for cooling or heating;

8. The grinding system is easy to clean, can quickly replace products, and is more suitable for the production of multi-color and small-batch materials;

9. High grinding efficiency, ensuring excellent grinding effect in a short time;

10. Imported high-performance hydraulic lifting, stable and reliable lifting;

11. Equipped with frequency converter, stepless speed regulation;

12. The grinding medium is imported high-purity zirconia beads, with a zirconium content of more than 95%

Working Principle

The motor of the hydraulic lifting basket grinder drives the lever and the bottom dispersing disc to rotate at high speed, so that the upper part of the dispersing disc and the inside of the basket cavity form a vacuum, and the slurry is sucked into the basket grinding cavity. The grinding media in the lever drive cavity generates forces in all directions, and the particles in the material are continuously collided and rubbed by the media, and the particle size becomes smaller and the particle size range is narrowed. The dispersing disc runs at a high speed and generates a vortex to suck out the materials in the cavity and recirculate them to the feed, which has a very significant dispersion and mixing effect. The hydraulic plunger is driven up and down through the work of the hydraulic pump, thereby driving the up and down of the entire transmission mechanism and the grinding device.