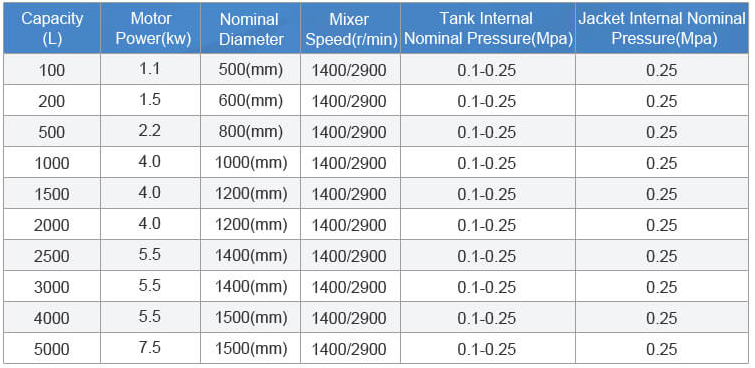

Product Parameters

Product Structure

The emulsification dispersion tank, also known as high-speed emulsifying tank, high-speed dispersion tank, suitable to continuously or cyclically produce such materials which need dispersion, emulsification, crush as cream, gelatin monoglyceride, milk, sugar, beverages, pharmaceuticals, and etc. After mixing, it can high-speed stir and disperse materials uniformly. With advantages of energy saving, corrosion resistance, strong production capacity, simple structure and convenient cleaning, it is an indispensable equipment for manufacturing dairy products, beverages and pharmaceuticals. The main configuration includes emulsifying head, air respirator, sight glass, pressure gauge, manhole, cleaning ball, caster, thermometer, level gauge and control system. Also we offer OEM solution according to clients’ requirements.

●Mixing tank mainly consists of tank body, cover, agitator, supporting feet, transmission device and shaft seal device.

●Tank body, cover, agitator and shaft seal can be made of carbon steel, stainless steel and other materials according to specific requirements.

●Tank body and cover can be connected by flange seal or welding. Also they could be with holes for purpose of feeding, discharging, observation, temperature measurement, manometry, steam fractionation and safety vent.

●Transmission devices (a motor or a reducer) are installed on top of the cover and the agitator inside the tank is driven by stirring shaft.

●Shaft sealing device can be used machine seal, packing seal or labyrinth seal, they are optional according to customer’s need.

Product Showcase

Stirring Paddle Type

Common Structure of the Stirring Paddle

We will select the appropriate stirring paddle type and stirring speed according to the characteristics of the mixing material and the user's process requirements.

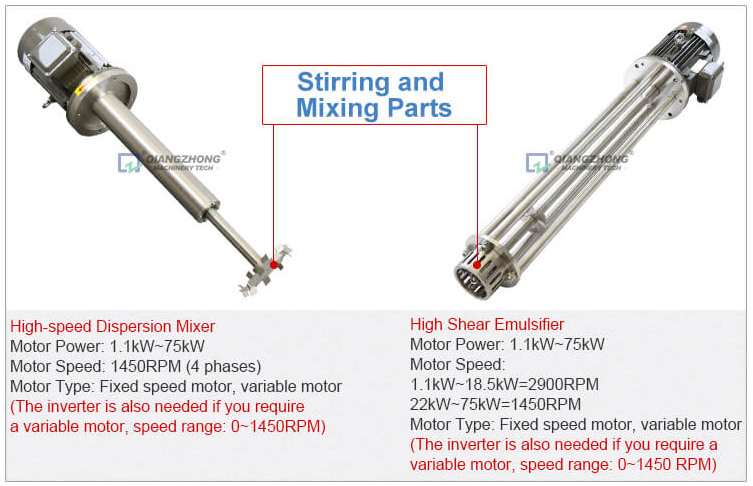

In addition to the above types of stirring paddles, some mixing tanks may also be equipped with a high shear emulsifier or a vane type dispersing mixer Its strong mixing force can quickly disperse and mix the materials.