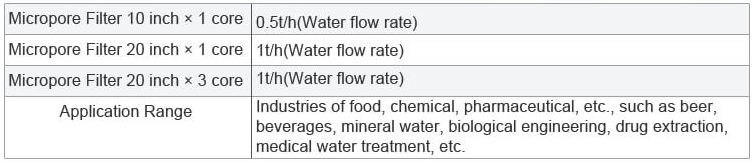

Product Parameters

Product Structure

•Microporous membrane filtration technology has been rapidly developed in recent years. It is a high-tech integrated high separation, concentration, purification and purification. Its features such as high filtration accuracy, wide application range, backflushing, compact structure, and simple operation makes it very welcomed by users.

•Microporous filter is mainly divided into stainless steel filter system, vacuum system, chassis and electrical appliances, etc., with reasonable structure, beautiful appearance, smooth surface, easy to clean.

•The filter consists of a microporous membrane filter, stainless steel housing, stainless steel tubing and valves. The filter is a cylindrical barrel structure made of 316 or 304 stainless steel. It uses a folded filter core as a filter element to remove particles and bacteria above 0.1 pm in liquids and gases.

• The microporous membrane is made of macromolecular chemical materials, pore-forming additives that are specially treated and then applied to the support layer. It has the advantages of convenient operation, high filtration precision, high filtration speed, low adsorption, no media shedding, no leakage, acid and alkali resistance. It can effectively eliminate bacteria and particles in injection water and liquid medicine, and has become the most widely used one in membrane separation technology.

Product Showcase

• The micropore filter has high filtration accuracy, fast transition speed, less adsorption, no media shedding, acid and alkali corrosion resistance, convenient operation, and wide application range. Now it has become a necessary equipment for the industry of pharmaceutical, chemical, electronics, beverage, fruit wine, biochemical water treatment, environmental protection, etc. Therefore, it is very necessary to maintain it, as it can not only improve the filtration accuracy, but also extend the filter service life.

• How to maintain the microporous filter well?

• Microporous filters can be divided into two types, namely precision microfilters and coarse filter microfilters. We need different, targeted maintenance and repairs based on different filters.

Precise Micropore Filter

•The core part of this filter is the filter element, which is made of special materials and is a consumable part, needing special protection.

•After the filter works for a period of time, its filter element deposits a certain amount of impurities, resulting in an increase in pressure and a decrease in the flow rate. Therefore, \V s necessary to remove the impurities in the filter in time and clean the filter element.

•When removing impurities, pay attention to avoid deformation or damage to the precision filter element Otherwise, damaged or deformed filter elements do not meet the design requirements for the purity of the filtered media.

• Some precision filter elements cannot be used repeatedly, such as bag filters, polypropylene filters, etc If the filter element is found to be deformed or damaged, it must be replaced immediately.

Rough Micropore Filter

•The core part of the filter is the filter core. The filter core is composed of a filter frame and a stainless steel wire mesh, which is a consumable part and needs special protection.

•After the filter works for a period of time, certain impurities are precipitated in the filter element, resulting in an increase in pressure and a decrease in the flow rate. Therefore, impurities in the filter core need to be promptly removed.

•When cleaning impurities, special attention should be paid to avoid deforming or damaging the stainless steel wire mesh on the filter core. Otherwise, the filter installed on the filter will not meet the design requirements for the purity of the filtered media, resulting in damage to the equipment of compressor, pump and instruments which are connected to it.

• If the stainless steel wire mesh is found to be deformed or damaged, it must be replaced immediately.