Video

Brief Introduction

Reverse osmosis (RO) water treatment equipment can filter out bacteria, viruses, heavy metals, pesticides, organic matter, minerals and odors in the water. Its production cost is very low, the pure water produced is of high quality, and the hygienic index is ideal. The treated water is pure water and can be consumed without heating.

Reverse osmosis water treatment equipment adopts advanced reverse osmosis desalination technology to prepare deionized water, which is a pure physical preparation technology. The reverse osmosis pure water unit has the advantages of long-term uninterrupted work, high degree of automation, convenient operation, long-term stable water quality, no pollutant discharge, and low cost of producing pure water.

Scope of application

1).Electronic industry water: pure water, distilled water, water for flushing electronic components such as integrated circuits, silicon wafers, display tubes, etc.;

2).Water for the pharmaceutical industry: large infusions, injections, tablets, biochemical products, equipment cleaning, etc.;

3).Process water in the chemical industry: chemical circulating water, chemical product manufacturing water, etc.;

4).Boiler feed water in the power industry: thermal power boilers, high-pressure boiler power systems in factories and mines

5).Food industry water: drinking purified water, beverages, beer, liquor, health products, etc.

6).Drinking water: bottled water, mineral water, direct drinking water from communities and schools, etc.;

7).Other process water: used for papermaking, electroplating, printing and dyeing automobiles, home appliance coating, coated glass, cosmetics, precision chemicals, etc.

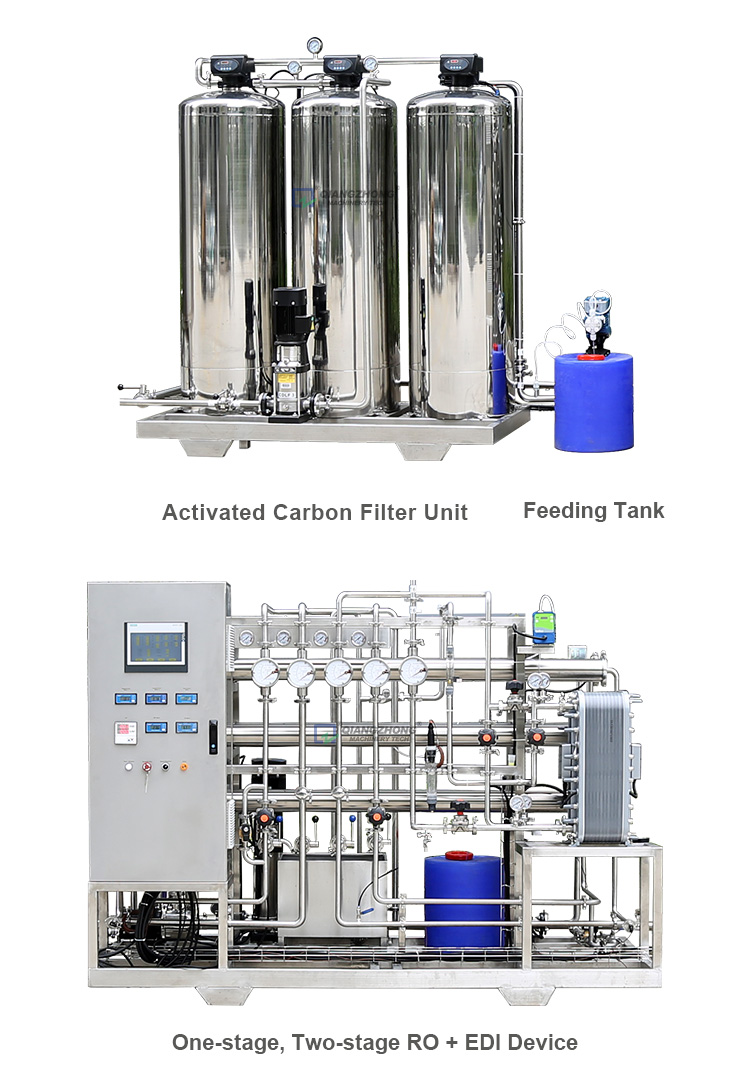

● The system design and the configuration of each functional unit are based on the raw water quality and user requirements specification(URS)

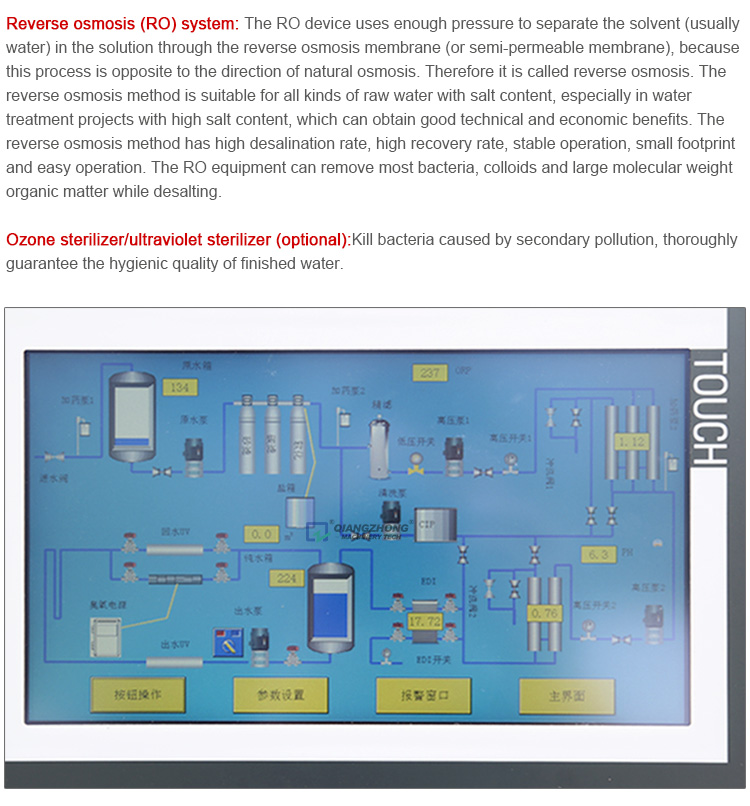

● The whole system is fully automatic + PLC control to ensure long-term stable operation, simple and convenient operation.

● Modular design and installation: reverse osmosis equipment and pretreatment are integrated in a rack, compact in structure and easy to install.

● Online water quality monitoring and control, real-time monitoring of water quality changes to ensure water quality safety.

● The system has a variety of device safety functions such as no water protection and high pressure, low pressure, and over pressure protection.

● Incorporating ergonomic design and humanized design, the operation is simple and convenient.

● The main components are imported components (such as Hyde Energy reverse osmosis ultra-low pressure membrane), which has high stability.

● Imported reverse osmosis membrane is adopted, with high desalination rate, stable operation and low energy consumption.

● The main part of the material is all well-known brands, quality is guaranteed, and designed according to the best configuration.

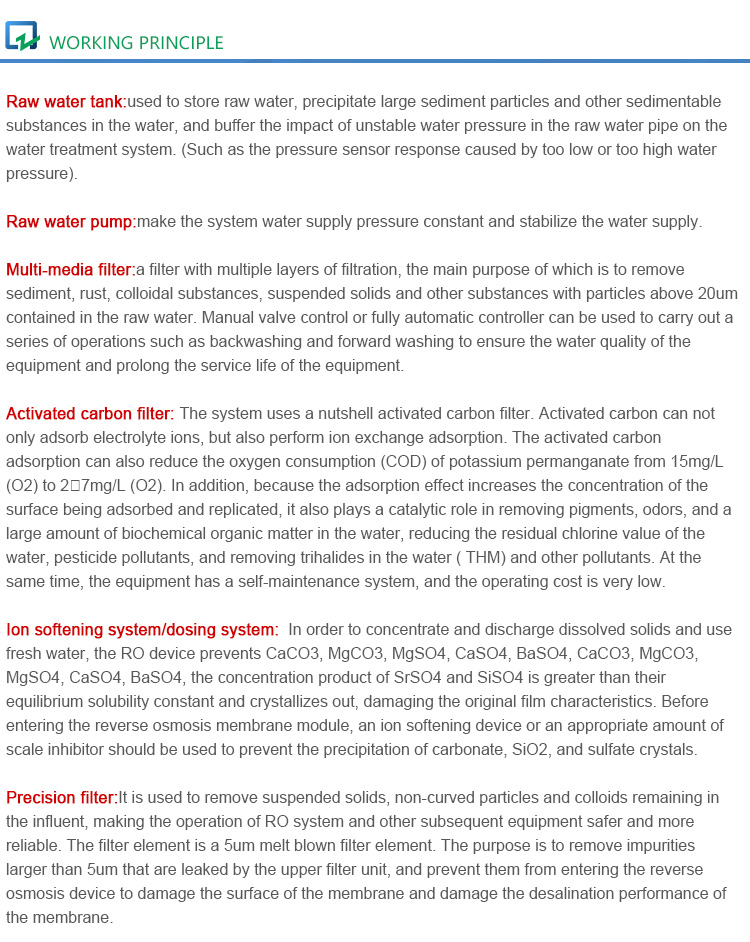

Structural Diagram

Raw water tank: used to store raw water, precipitate large sediment particles and other sedimentable substances in the water, and buffer the impact of unstable water pressure in the raw water pipe on the water treatment system. (Such as the pressure sensor response caused by too low or too high water pressure).

Raw water pump: make the system water supply pressure constant and stabilize the water supply.

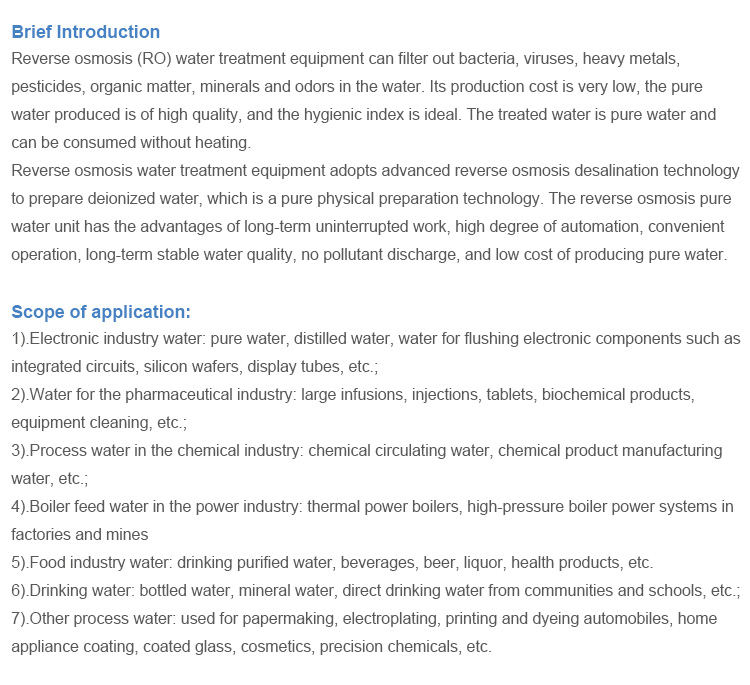

Multi-media filter: a filter with multiple layers of filtration, the main purpose of which is to remove sediment, rust, colloidal substances, suspended solids and other substances with particles above 20um contained in the raw water. Manual valve control or fully automatic controller can be used to carry out a series of operations such as backwashing and forward washing to ensure the water quality of the equipment and prolong the service life of the equipment.

Activated carbon filter: The system uses a nutshell activated carbon filter. Activated carbon can not only adsorb electrolyte ions, but also perform ion exchange adsorption. The activated carbon adsorption can also reduce the oxygen consumption (COD) of potassium permanganate from 15mg/L (O2) to 2~7mg/L (O2). In addition, because the adsorption effect increases the concentration of the surface being adsorbed and replicated, it also plays a catalytic role in removing pigments, odors, and a large amount of biochemical organic matter in the water, reducing the residual chlorine value of the water, pesticide pollutants, and removing trihalides in the water ( THM) and other pollutants. At the same time, the equipment has a self-maintenance system, and the operating cost is very low.

Ion softening system/dosing system: In order to concentrate and discharge dissolved solids and use fresh water, the RO device prevents CaCO3, MgCO3, MgSO4, CaSO4, BaSO4, CaCO3, MgCO3, MgSO4, CaSO4, BaSO4, the concentration product of SrSO4 and SiSO4 is greater than their equilibrium solubility constant and crystallizes out, damaging the original film characteristics. Before entering the reverse osmosis membrane module, an ion softening device or an appropriate amount of scale inhibitor should be used to prevent the precipitation of carbonate, SiO2, and sulfate crystals.

Precision filter: It is used to remove suspended solids, non-curved particles and colloids remaining in the influent, making the operation of RO system and other subsequent equipment safer and more reliable. The filter element is a 5um melt blown filter element. The purpose is to remove impurities larger than 5um that are leaked by the upper filter unit, and prevent them from entering the reverse osmosis device to damage the surface of the membrane and damage the desalination performance of the membrane.

Reverse osmosis (RO) system: The RO device uses enough pressure to separate the solvent (usually water) in the solution through the reverse osmosis membrane (or semi-permeable membrane), because this process is opposite to the direction of natural osmosis. Therefore it is called reverse osmosis. The reverse osmosis method is suitable for all kinds of raw water with salt content, especially in water treatment projects with high salt content, which can obtain good technical and economic benefits. The reverse osmosis method has high desalination rate, high recovery rate, stable operation, small footprint and easy operation. The RO equipment can remove most bacteria, colloids and large molecular weight organic matter while desalting.

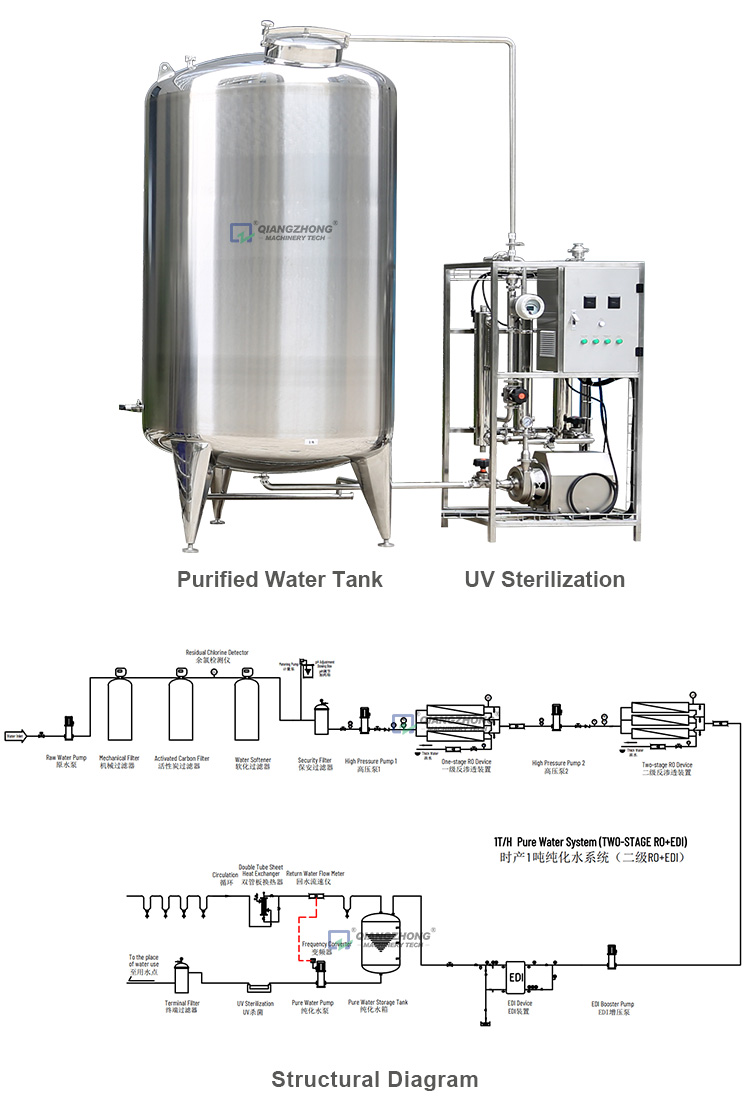

Ozone sterilizer/ultraviolet sterilizer (optional): Kill bacteria caused by secondary pollution, thoroughly guarantee the hygienic quality of finished water.