The frame filter is suitable for industries such as biological products, medicine,brewing.food and beverage, tobacco, water treatment, petrochemical. environmental protection, etc for precision filtration. clarification sterilization, purification treatment, etc. It can also filter the injection, infusion and other liquids in the pharmaceutical industry with good performance. The filter can also filter by means of a filter layer formed by a primary filter layer or a filter aid (for example, diatomaceous earth.clay,activated carbon,etc.)to obtain a clean liquid. According to the different iltration accuracy (crude filtration.fine filtration) requirements of the filtrate, customers can choose different filter materials for different filtration precision; and increase or decrease the number of layers of filter plates according to the production volume.

The filter has the advantages of lessfiltrate loss, large circulation,simple operation,convenient disassembly and assembly, and easy cleaning. The filter plate adopts a special structure of a flat threaded mesh shape, which is smooth and flat. and the filter material (filter cloth,flter paper.filter membrane) is not easily damaged. and can effectively prolong the service life of various filter materials thereby reducing the production cost. The flter is equipped with a stainless steel pump.which has low motor power and low power consumption. The rubber wheel is mounted under the frame for flexible movement and light weight.

PRODUCT PARAMETERS

|

Model No |

Motor Power(kw) |

Filter Pressure Filter Size Filtration Water Filtration Layers of Dimensions |

||||||

|

(Mpa) |

(mm) |

Area(nf) Flow(t/h) Medium(um) Plates |

(L*W-H) |

|||||

|

WBG-100 |

0.55 |

0.15 |

100 |

0.078 |

0.8 |

0.8 |

10 |

680x310x580 |

|

WBG-150 |

0.75 |

0/15 |

150 |

0.17 |

0.15 |

0.8 |

10 |

780x350x700 |

|

WBG-200 |

1.1 |

0.15 |

200 |

0.34 |

2 |

0.8 |

10 |

820x380x760 |

|

WBG-300 |

1.1 |

0.15 |

300 |

0.7 |

4 |

0.8 |

10 |

920x500x900 |

|

WBG-400 |

1.1 |

0.15 |

400 |

1.25 |

6 |

0.8 |

10 |

1260x600x1120 |

|

WBG-400 |

1.5 |

0.15 |

400 |

2 |

9 |

0.8 |

16 |

1350x600x1150 |

|

WBG-400 |

1.5 |

0.2 |

400 |

2.5 |

10 |

0.8 |

20 |

1420x600x1180 |

|

WBG-400 |

22 |

0.3 |

400 |

4 |

13 |

0.8 |

32 |

1588x600x1180 |

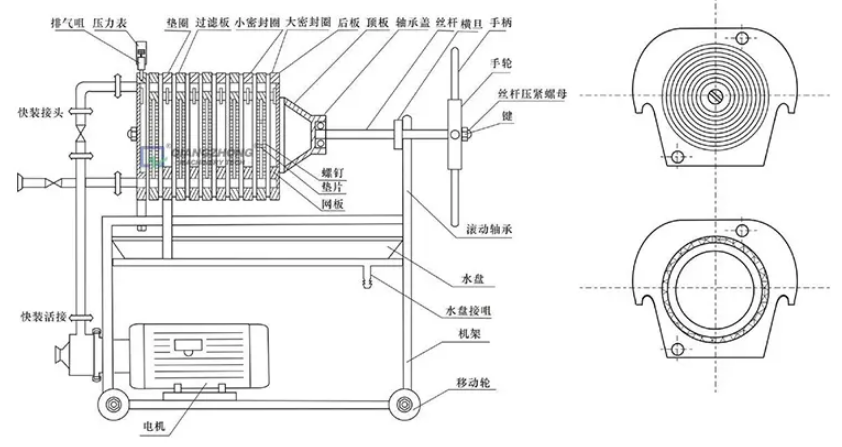

PRODUCT STRUCTURE

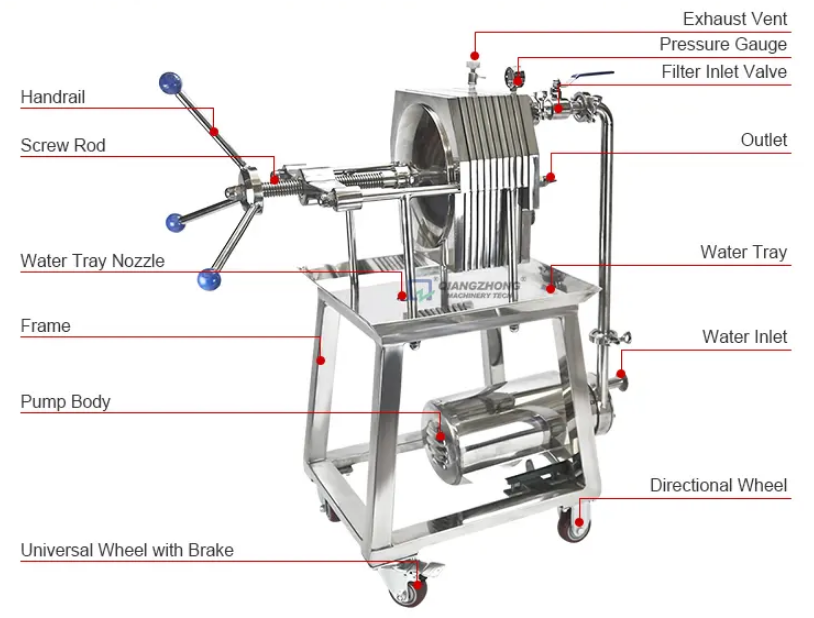

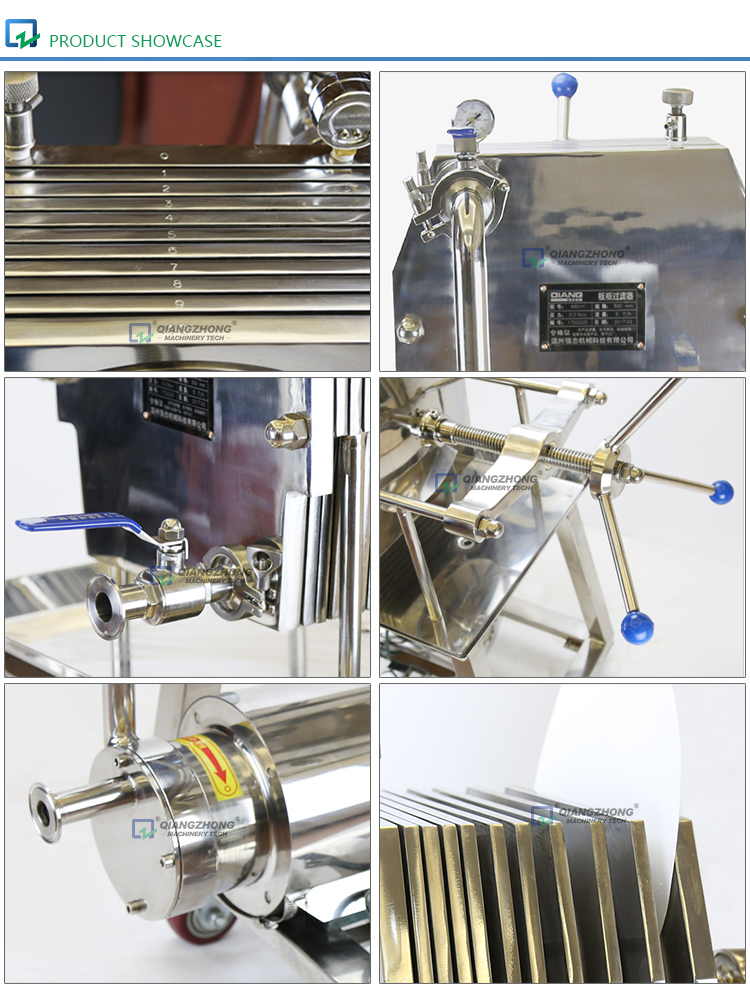

Except the motor, the other parts of the machine are made of 304 or 316L high-quality corrosion- resistant stainless steel, suitable for filtering all kinds of PH value of the acid-base solution. The machine adopts pressurized airtight filtration,low filter loss, good filtration quality and high efficiency. The filter section is composed of ten filter plates, with a large filtration area and a large circulation volume. According to the production process requirements (preliminary care, decarbonization, particulate removal, semi-fine filtration, fine filtration) of the solution to be filtered, different filter membranes can be replaced, and the number of filter plate layers can be appropriately reduced or increased according to production flow requirements to meet the production needs. Therefore, this machine is a multi-use machine with a wide range of features. The filter plate adopts a plane thread mesh structure, which is an advanced structure, no deformation, easy cleaning, and it can effectively prolong the service life of various filter membranes and save the production cost. This machine is equipped with stainless steel infusion pump with a small power motor of power consumption. Rubber wheels are installed under the base for mobile use, flexible movement and easy operation.

PRODUCT INTRODUCTION

This machine is a stainless steel multilayer frame filter press.It is suitable for the closed fitration of liquids with a concentration less than 50%,low viscosity, and low slag content to achieve the effects of fine filtration, decarbonization, and semi-fine filtration. It uses microporous membranes directly for sterile filtration. This machine has a large filtration area, large flow, and a wide range of applications,so it is widely used in pharmaceutical, chemical, food and other industries, especially for pharmaceutical injections, liquid filtration, the effect is very good.

The design idea of the plate-type filter was inspired by the cardboard filter, and this filter is fine

manufactured after innovation and improvement. The product has a novel appearance and practicality It can fit various kinds of fiter materials such as filter cloth, filter paper board,filter film, etc. It can meet the requirements of different precision, grades and filtration processes of many kinds of liquids.

Two inlet and outlet connecting pipes are used for the inlet and outlet ports, which greatly increase the flow rate and ensure that it is pressed evenly during operation. Two glass sights can visually observe the difference of liquids between pre-filtration and post-filtration; the pressure gauge above the feed inlet clearly shows the state of working pressure during iltration; the sampling valve above the discharge port can not only facilitate the sampling of liquid material after filtration, but also can be used to perform deflation and emptying operation at the time of turning on and shutting down the filter. but also can be used for deflation and discharge when turning on and turning off the machine. The tri-clamp connector is very convenient for installation and removal. The matching valve and fittings conform to ISO and other health standards and they are exquisitely manufactured and can be integrated with the pipelines in the workshop

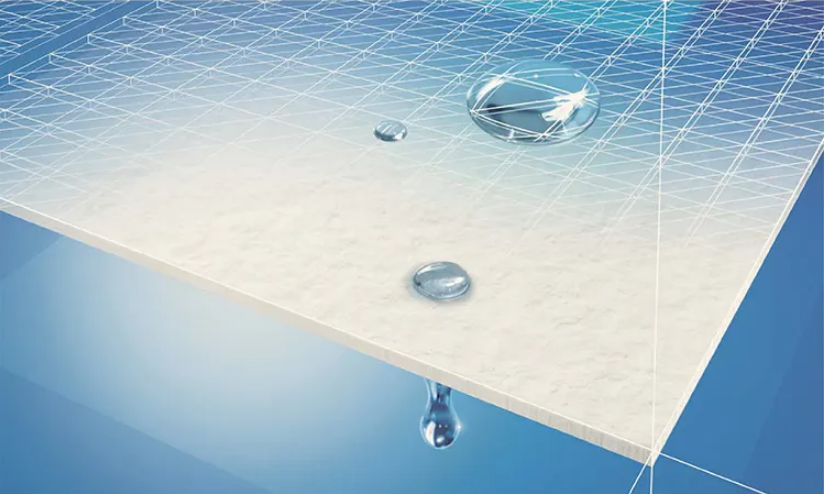

Film ilter:

The film filter material made of mixed fibers meets the quality standards, and its product surface is smooth, light and thin, with high porosity and uniform pore structure, so it has the characteristics of high flow velocity and low adsorption.

This product is suitable for the pharmaceutical industry, biological products, electronics industry, brewing, watches and other industries, and it can filter medical oil. lubrication oil.fuel oil. etc.filter bacteria and particles. It is also used for scientific research experiments, laboratory.etc. Generally it can remove 0.65um particles, bacteria below 0.45um.

Instructions for use:

●Place the filter membrane in a clean container and soak it in distilled water of about 70℃C.After soaking it for about 4 hours, rinse it with distilled water of appropriate temperature before use.

●Put the cleaned fiter (wet) into a suitable filter to prevent leakage from the surroundings. Put the fitrate from the inlet and discharge the air at the exhaust port, then the machine could work for filtration.

Polypropylene (PP) filter instructions for use:

PP filter membrane is made of polymer material, non-toxic, widely used in medicine, chemical industry, food, beverage, alcohol and other fields.

The PP filter membrane can withstand high temperatures up to 121°C. 30 minutes hot pressure disinfection, working temperature below 100 “C.

The PP filter membrane has a good strength, no deformation,no media fall off.no re-contamination. First use 70% ethanol to infiltrate the filter for several minutes.

PP filter membrane adapt depth filtration,resistance is small, fast flow.It is especially suitable for position difference filtering, such as achieving higher flow in low dropout conditions and long service life.

USE AND MAINTENANCE INSTRUCTIONS

- When installing or replacing the filter materiaL it should be tightly attached to the silicone rubber ring, the position must be moderately flat, and then press the moving plate to prevent leakage.

- If you want to stop the equipment. please first close the inlet ball valve, and then cut off the power to prevent the liquid back against the impact and destroy the filter membrane.

When maintaining the filter. first wash it with 3%-5% sodium bicarbonate solution. rinse it again with clean water and pure water, finally sterilize, and check the PH value to ensure that it reaches the allowable range.

|

I |

Pump couldn’t switch on or overload at startup |

1. motor or power failure 2. pump stuck 3. discharge valve is not closed |

1. check the motor or power supply 2. inspection pump casing, impeller 3. close and restart the discharge valve |

|

II |

Pump does not discharge |

1.insufficient liquid or gas not drained in airbag 2.wrong direction of motor rotation 3.the speed is too low 4. the suction height is too high |

1. refill the pump 2. check and correct direction of rotation 3. check and adjust speed 4. reduce the suction height |

|

III |

Pump discharge interruption |

1. suction pipe leakage 2. gas not drained in airbag 3. inhalation is blocked by foreign matter 4. a lot of inhaled gas |

1. check and repair suction connection and the sealing 2. refill the pump 3. stop the pump and remove foreign materials 4. check whether there is vortex at the inlet and whether flooding depth is too shallow. etc. |

|

IV |

Insufficient Flow |

1. same with (II). (Ill) 2. the system static lift increase 3. increased resistance loss 4. pump impeller blockage 5. leakage |

1. take corresponding measures

3. inspect pipeline and the check valve 4. cleaning and exchange impeller

|

|

V |

Insufficient Lift |

1. same with (II). (Ill) 1JIV)4

3. too much flow |

1. take corresponding measures 2. check the nature of related materials 3. reduce the flow |

|

VI |

Noisy |

1. the impeller and the pump casing friction 2. same with (V) 3 3. increase of liquid unit weight 4. the pump shaft bending |

1. inspect and replace the faulty parts 2. take corresponding measures 3. check unit weight 4. replace the pump shaft |

|

VII |

Equipment vibration |

1. samer with the (III) 4 2. surging 3. impeller damage |

1. take corresponding measures 2. check the discharge of liquid and pressure levels 3. inspect and replace the impeller |